material hardness testing methods|different types of hardness testing : dealers Rockwell hardness test is a fast testing method found for production control, with direct reading, used primarily for metallic materials. Rockwell hardness (HR) is calculated by measuring the depth of the indentation after inserting the indenter into the sample material at a given load, which reflects the measured resistance of the metal to indentation.

ASC manufactures Autoclaves & Ovens. Offices in the UK, USA and China. ASC designs and builds autoclaves from Lab scale to 10m diameter x 60m long. Operating .

{plog:ftitle_list}

Todas as autoclaves TLV-FA são equipadas com tecnologia de esterilização de última gera.

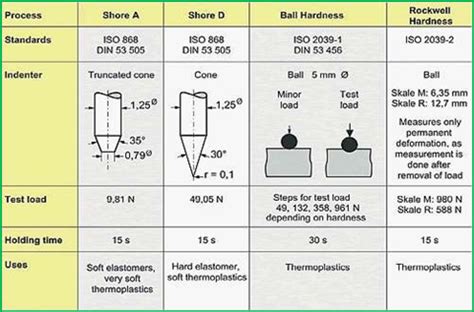

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most .

The Brinell hardness testing method is commonly used to test large or coarse-grained materials like nonferrous metals, castings, and forgings. This hardness testing involves applying a known load to a spherical indenter, typically made of hardened steel, although a tungsten carbide ball may be used for harder materials. Q: What types of hardness testing methods are there? A: Rockwell (ASTM E18), Brinell (ASTM E10), Vickers, Knoop (ASTM E384) and dynamic hardness testings are some different types of hardness testing .

To determine dynamic hardness, the indenter is forced under high loading rate which leads to impact or chock the test material. Thus, the indenter could be shot the tested material like a projectile onto the target surface (Low 2006; El-Ezz 2007).The test material must be permanently deformed, so the kinetic energy should be chosen to assure plastic .

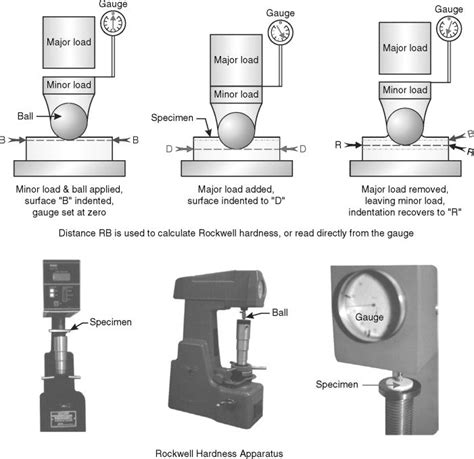

Hardness testing methods vary based on the material and heat treatment chosen. It’s important that engineers specify hardness testing methods correctly to ensure timely heat treatment and avoid costly delays. . Then, a heavy load (anywhere from 15 kgf to 150 kgf, depending on the material and its strength) is applied and held for a period . Rockwell hardness test is a fast testing method found for production control, with direct reading, used primarily for metallic materials. Rockwell hardness (HR) is calculated by measuring the depth of the indentation after inserting the indenter into the sample material at a given load, which reflects the measured resistance of the metal to indentation. Four Material Hardness Test Methods. Measuring the hardness of materials is a fundamental aspect of material science and engineering, involving various test methods each suited to specific types of materials and applications. These methods not only help in determining the hardness but also provide insights into other material properties like .

Each type of hardness testing method employs specific techniques to assess this resistance, resulting in different hardness scales and values. In general, the principle involves applying a known load to an indenter and measuring the resulting indentation or impression on the material’s surface. Methods of Hardness Testing There are five commonly-used methods of hardness testing: (a) Brinell hardness test, (b) Rockwell hardness test, (c) Vickers test, (d) Knoop hardness test, and (e) Microhardness test. . In the Brinell hardness test, the test material is indented by use of a 10-mm-diameter hardened- steel/carbide ball that is subjected to a specified load, F . (4) Selection of F and D (principle of geometric similarity of indentation) When measuring Brinell hardness with indenters of different diameters and loads of different sizes, the principle of geometric similarity must be met to obtain the same HB value, that is, the opening angleφ of the indentation is equal.. Method: The same HB shall be measured for samples with .

When selecting a hardness test method, important considerations include: The type of material to be hardness tested; Whether compliance with a standard is required; . Before hardness testing of metallic materials or other materials, you must prepare the surface. The required surface condition depends on the type of test and load used. The full range has only 20 graduations so a typical instrument is limited when testing metallic materials. 7. Leeb Hardness Testers. The Leeb hardness testing method, also known as the Equotip method, was first invented by a swiss company in 1975. This method measures the velocity of rebound when a carbide ball or diamond-tipped head is . This article provides an overview of common hardness testing methods for metals, comparing their applications, benefits, and drawbacks. . The Brinell hardness test measures material hardness by determining the diameter of an indentation made by a hardened steel or carbide ball under a specific load. A load, typically ranging from 500 to 3,000 .Common Hardness Testing Methods. When it comes to evaluating the hardness of a material, various testing methods are available. Each method is unique in its approach and application but shares the common goal of determining a material’s resistance to .

Materials that fall into a very high hardness scale or thin and small components tend to be better suited for Knoop or Vickers testing. Vickers methods are widely used for microhardness testing, which is essential for measuring the hardness of small or thin materials or for analyzing the hardness of specific microstructures in a material. This . Rockwell Hardness Standard Test. The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter into the surface of a material. Hardness is evaluated by measuring the difference in depth of .

types of hardness testing methods

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.Material Hardness – Types, Testing Methods. by Jignesh Sabhadiya. Hardness is a material’s quality to withstand localised deformation. It may be especially important when looking for a suitable material for an environment that includes little particles that can induce material wear. Soft materials suffer indentations while hard ones resist .This test is otherwise known as the microhardness test method used for thin sections or small parts. This test specifies a range of light loads using a diamond indenter. . a proper material hardness test is of utmost importance to determine the most suitable material for your project. Based on our experience, we offer varieties of hardness . The Rockwell hardness test is a method where the material in question is indented using either a diamond cone or a hardened steel ball. Initially, a minor load, often 10 kgf, denoted as F0, is applied to the material (refer to Fig. 1A). Once the material has settled under this load, an indicator, which tracks the indenter's movements and thus .

leco vickers hardness tester

Applications of Rockwell Hardness Test. Quality Control: Commonly applied in industries that require hard materials on parts and other manufactured products. Material Selection: This tool supports the process of identifying materials that will be applicable depending on the hardness needed. Heat Treatment Evaluation: Using the assessment of the hardness of the treated . Brinell Hardness Test (ASTM E10) Rockwell (ASTM E18) Vickers; Knoop ; Brinell v Rockwell Hardness Test Hardness Test Characteristics General characteristics of hardness-testing methods and formulas for calculating hardness. Hardness Scale. The chart below is used for converting various hardness scales. Since all the hardness test are limited in .

There are a number of different methods of testing the hardness of a material through indentation. The three most commonly used are the Brinell test, the Vicker’s Diamond test, and the Rockwell test. All three methods involve indentation of the material. The hardness is calculated by measuring the force applied and comparing this to some .

lee brinell hardness tester

principle of hardness tester

The results of experimental studies on the optimal method of testing materials for hardness depending on physical and mechanical properties are presented. The possibility of evaluating the structural parameters, i.e., the homogeneity coefficients and the variation of the reliability of various devices for obtaining the hardness values of rolled metal products, is . There are three primary procedures for determining a material’s hardness: scratch hardness testing, the Leeb rebound hardness test, and indentation hardness testing. Scratch hardness testing The Mohs scale of hardness can be used to determine the hardness of a material by comparing it to a list of standard materials with known hardness. In stainless steel standards, three hardness testing methods, Brinell, Rockwell, and Vickers, are typically stipulated, measuring HB, HRB (or HRC), and HV hardness values respectively. . ASTM E18 standard provides detailed guidelines for Rockwell hardness testing of metallic materials, including specific requirements for stainless steel rods. .

1.2. Brinell Hardness Test: The oldest of the hardness testing methods in common use on engineering materials today is the Brinell hardness test, invented by Dr. J. A. Brinell in Sweden in 1900. The Brinell test uses a desktop machine to apply a specified load with a hardened sphere of a specified diameter.

The optimal method for hardness testing and the suitable load vary based on factors such as the material being tested, the specific application, the shape and surface quality of the component, its intended use, and the specific requirements of the customer.

how to test for hardness

Plastic materials that withstand steam autoclaves - Polysulfone, Ultem®, PPSU, PEEK for medical applications, components and devices at Curbell Plastics.

material hardness testing methods|different types of hardness testing